Thanks to technological advances and the onset of the automation era, human-powered devices increasingly became a thing of the past, giving way to their automation through the use of actuators. With the purpose of improving people’s wellbeing and comfort, today linear and rotary actuators are widespread and on high demand, but before taking a closer look at them, we will give you an overview on what an actuator is and the different types in existence. Let’s get to it!

When speaking of mechanical actuators, we are referring to an inherently mechanical mechanism whose function is to provide a force to move another mechanical device. The force generated by an actuator comes from three possible sources: pneumatic pressure, hydraulic pressure or electric motive power. This means that, depending on the source of the force, the actuator will be called ‘pneumatic’, ‘hydraulic’ or ‘electric’.

You will find this article interesting: Success story: reduced actuators for locksmithing

What types of actuators are there?

The most common types of actuators in industry are:

Hydraulic actuators

They use pressurized liquids to generate a mechanical force. One of the most widespread liquids is oil. These actuators are employed when high power is required, in heavy and large machines. They require a plentiful energy supply, as well as periodic maintenance.

There are three large groups:

- Hydraulic cylinder

- Hydraulic motor

- Hydraulic oscillating motor

Electronic actuators

They are driven by electric currents. Some consume a high amount of energy, and as a result, in these cases controllers are used.

Their structure is simpler when compared to that of hydraulic and pneumatic actuators, since they only require electric energy as a source of power.

They are commonly used in mechatronic devices such as robots, or to control repetitive tasks, such as the ignition and shutdown of HVAC systems.

Pneumatic actuators

They convert the energy of compressed air into mechanical work. Even though, in essence, they are identical to hydraulic actuators, in this case the compression ratio is lower.

Pneumatic models imply simple positioning motions. An actuator of this type may work in a linear or rotary motion.

You might be interested in: Use of actuators with Arduino

Difference between linear and rotary actuators

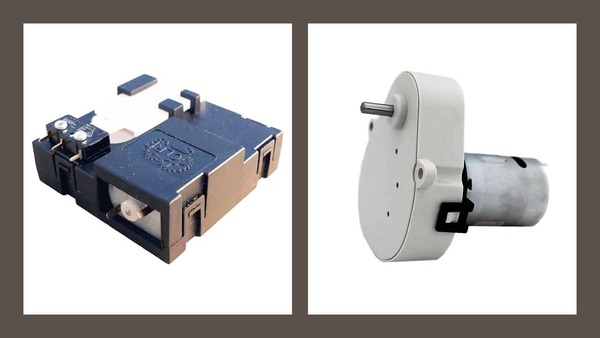

A linear actuator is a device that turns the rotary motion of a direct current, low-voltage motor into a linear motion. Its output motion is in line with the output shaft itself. This makes it possible to elevate, adjust, tilt, push or pull heavy or hard-to-reach items with just the push of a button.

Its installation is very easy when compared to hydraulic systems, and it also requires much less space.

A linear actuator is composed of a motor, a gear and an axle thread that includes a nut. Its most widespread application would be the opening of large windows or vents.

Keep learning: The role of sensors and actuators in autonomous vehicles

As for rotary actuators, they are those whose output motion is circular. Their purpose is to convert the hydraulic pressure of a fluid into rotational power, and output an instant torque.

They have a cylindrical chamber that includes a stationary barrier and a central shaft with one or two vanes attached.

Power is obtained by applying the hydraulic pressure over the entire surface of the vanes, which, when moving, cause the shaft of the actuator to rotate. The torque generated by an actuator will depend on the surface of the vane and the hydraulic pressure to which the chamber is subjected.

The speed, just like with any oil-hydraulic dynamic element, will depend on the flow that circulates through the actuators, and is usually adjusted using choke valves.

Rotary actuators may be mounted vertically, horizontally or slantwise. However, since these are elements that are subjected to extremely high torques, their fastening needs to be studied in relation to the forces involved.

They may be used in a great variety of industrial applications, such as pressure clamps, opening and closing of large-scale valves or saw blades. But one of the most widespread applications is their use in automated shutters.

When opting for one or the other, the determining factor is the end purpose. For example, for a pushing motion, it will always be simpler to adapt a linear actuator than a rotary one. If, conversely, we are referring to a device that needs to perform a tugging motion or roll something up, it will be simpler to use a rotary actuator.

Recommended reading: Sound pleasantness in gear motors and actuators

At CLR we have been working on the design and manufacturing of gear motors and actuator solutions for over four decades. If, after reading this post, you still have doubts about which actuator to choose, get in touch with us; our team of engineers will help you based on your needs.