Some aspects that are usually taken into account by machinery manufacturers are the properties of the sounds produced by drive systems. The level and quality (pleasantness) of the gear motor’s sound, where different frequencies come into play, has a significant incidence on the perception of the product’s perfection by the end user. In this article we will study the course of action toward a correct study of speed reducer and actuator sounds. Make a note!

Aspects such as the location of the machine call for specific noise levels. For example, while domestic vending machines produce almost imperceptible sounds, outdoor machines aim to have a certain sound level, as an indication of its operation and report.

But, how can offending noises be limited? It is not necessarily the most silent design one should aim for, but instead, the most adequate for each product and consumer. It is most recommended to perform a sound analysis based on the location and target users.

The concept of sound “pleasantness”

When speaking of the “sound quality” of a product, we find many more aspects in addition to “pleasantness”. In order to determine how pleasant or unpleasant a sound is there are a few predefined metrics, such as “annoyance” or “sensory pleasantness”. Generally, these metrics are combinations of other parameters that arise from certain events in the gear motor’s sound, such as sound level, sharpness, roughness, fluctuations and tonality. However, there is no generic metric to describe pleasantness for all products.

Going back to speed reducers and different actuator solutions, it is not just important to pay attention to decibel levels, but it is also key to study frequencies and vibrations generated during their operation, with sights on reaching the highest acceptance of the product by consumers.

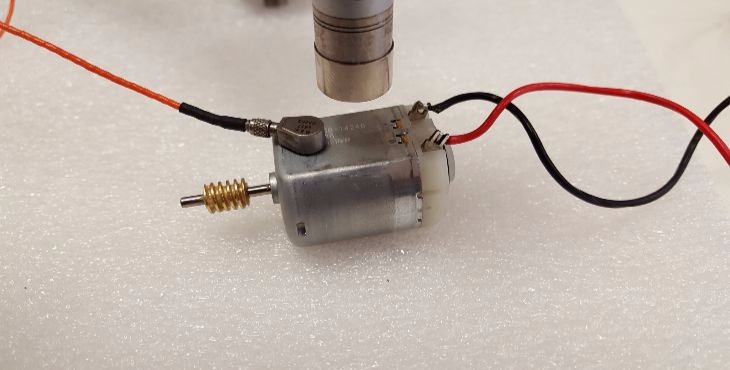

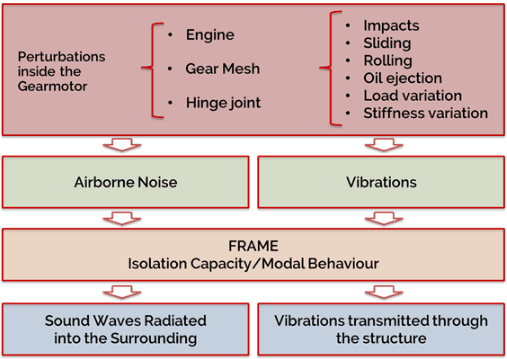

We can find two main sources for noise: the motor and the gears. These two sources act quite similarly, generating aerial noise and transmitting vibrations to the speed reducer’s housing. In the case of a kinematic chain, vibrations are produced due to the contact between the gear teeth. This generates a noise that is transmitted through the air, and at the same time, a vibration that reaches the housing of the speed reducer through the various transmission paths (shafts, supports…).

Reducing noise

In order to reduce the noise generated by the speed reducer, whether as a result of vibrations or air propagation, it is fundamental to design all components properly. On the one hand, the correct functioning of gears should be ensured, maximising meshing stiffness and reducing the transmission error. The use of helical gears guarantees a higher contact between gears, and therefore, helps reduce the noise generated. On the other hand, the final speed reducer’s configuration should be carefully studied, analysing the structure’s vibration and preventing resonances.

“In order to prevent noise issues, CLR carefully analyses each of the speed reducer’s components, always with sights on the client’s final application”.

Pedro Poveda, CLR Sound Engineer.

Lastly, the connection between the speed reducer and the final application where it is to be installed should be especially taken into consideration. At times, using a speed reducer in a project it was not designed for may lead to a considerable increase in vibrations and sound emissions. For this reason, it is important to be aware of the final application and design for it taking into account the speed reducer’s characteristics, since it will be one of the main sources of noise.

Which tests guarantee a suitable sound for the gear motor?

Sound pressure level measurements should be carried out based on client requirements or standards (e.g., UNE-EN ISO 11201 for workstation machinery). Likewise, vibration measurements should be performed to ensure the proper operation of the speed reducer. An additional study involves psychoacoustic trials with the purpose of finding user preferences.

You might be interested in: Guide to prevent mechanical vibrations in your machines.

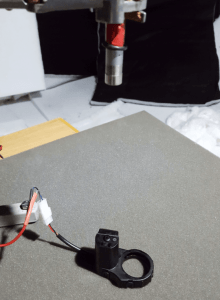

Based on sound samples taken from various products, a group of users is subjected to an acoustic test. During each test, each participant will listen to the samples and evaluate them based on a specific parameter (quality, pleasantness, annoyance…). As a result, the product is adapted to user preferences. Another aspect to keep in mind is related to the transmission gear friction levels. These gears are more efficient when subjected to heat treatments that dissipate heat and limit effort due to friction.

“CLR has managed to reduce noise by over 5 dB(A) in some of its products thanks to improvements such as using different motors or materials, or by using helical gears in the kinematic chain”.

Pedro Poveda, CLR Sound Engineer.

At CLR we are aware that sound is one of our clients’ greatest concerns, which is why our sound engineering team analyses each project and, through the use of cutting-edge sound and vibration measuring technology, ensures that each products leaves the factury with the highest quality guarantees. Are you dissatisfied with your current speed reducers? Do you want to improve over your standard gear motors and use one that is tailored to your needs? Contact our engineering team and let us know what you need.