In the following interview with our Sound Engineer, Pedro Poveda, we discuss one of the most concerning issues for our clients when facing an improvement of their speed reducers: the correct measurement of acoustic pressure.

As a gear motor manufacturing company with a track record of over 40 years, we always aim to comply with the highest acoustic standards in order to achieve full customer satisfaction and the accomplishment of their strategic goals. Do you want to learn about the acoustic pressure tests we perform and the results we obtain? Keep reading!

What is acoustic/sound pressure when referring to industrial machinery or equipment?

The vibrations generated by the various components of a machine result in a disturbance that propagates as a waveform undulation of air particles. This motion produces small variations in the atmospheric pressure. The difference between the dynamic pressure and the atmospheric pressure is known as acoustic pressure.

Which acoustic pressure studies are performed at CLR?

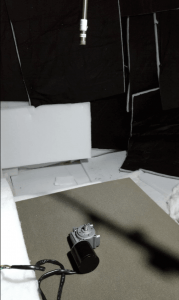

In order to determine the acoustic power level generated by a speed reducer, sound pressure measurements are performed in an anechoic and semi-anechoic chamber as per various standards, such as the ISO 3744 or ISO 3745 standards.

What measuring instruments are used?

CLR has sound level meters in order to determine the level of sound pressure emitted by its products. Moreover, it uses measuring microphones to determine the level of acoustic power and an intensimeter to learn about the sound intensity generated by the speed reducers.

What is the effect or connotation of the different levels of acoustic pressure or sound frequencies?

In certain cases, the client establishes minimum requirements in regard to sound that the speed reducers should comply with. On certain occasions, these requirements are set forth by some standard, such as for vehicle folding side view mirrors (TL_82398 standard). As a general rule, a maximum sound pressure level that the device cannot exceed is established.

In regard to the way in which the human ear works and as per the A-weighting system employed in most cases, low frequencies (under 400 Hz) are perceived as a lower sound level by the hearer. This same phenomenon takes place for frequencies over 16000 Hz. It is therefore important to put emphasis on the range of measured frequencies (400 – 6300 Hz), since the hearer will perceive them more sharply.

When speaking of the sound emitted by speed reducers, what are the components that influence the most the final sound that the speed reducer makes?

The final sound of the sample is influenced by a myriad of factors. A proper component design in regard to dimensions, materials, or even the selection of the motor to be used, can considerably affect the noise. Likewise, the ways in which the housing vibrates may result in undesired resonances and, therefore, an amplification of the noise. Conversely, a high quality manufacturing process guarantees the correct finishing and assembly of the components, and therefore prevents the emergence of certain undesired noises.

You might be interested in this eBook by CLR: “Gear calculation: reducing vibrations and boosting efficiency in your transmissions”

And lastly, by how much were dB levels and undesired vibrations cut down in the last few projects developed by CLR?

Noise reduction is a continuous and gradual process, which is accomplished thanks to a continuous product improvement process. CLR has managed to reduce noise in more than 5 dB (A) in some of its products thanks to improvements such as using different motors, materials or using helical gears in the kinematic chain. All of these improvements translate not only into a lower sound pressure or vibration level, but they also result in an improvement in the way the device is perceived sound wise, reducing rattling and modulations in the noise generated by the speed reducer. This leads to a more stable and continuous sound behaviour, conferring a higher quality level to the product.

As our partner Pedro explained, it is very important for your speed reducer supplier to have the best technological resources and enough experience in order to ensure the highest sound quality in your products. Are you unhappy with the noise generated by your speed reducers? Do you have a new project and are concerned about the sound the speed reducer may generate? CLR can help you meet your project’s sound standards. Tell us, how can we help you?