These devices transform hydraulic, pneumatic or electric energy into the activation of a process whose purpose is to generate and effect or action in an automated process. Their application is widespread in the automotive industry, but do you know how they are applied to the various pressure-based systems in vehicles?

High reliability, simple use, minimal maintenance, safety and motion precision… If you are looking for these properties in your actuation mechanisms, you will need to carefully study which type of actuator is the most suitable for each project, because depending on the work we need to perform, we will obtain a very different performance.

Types of mechanical actuators

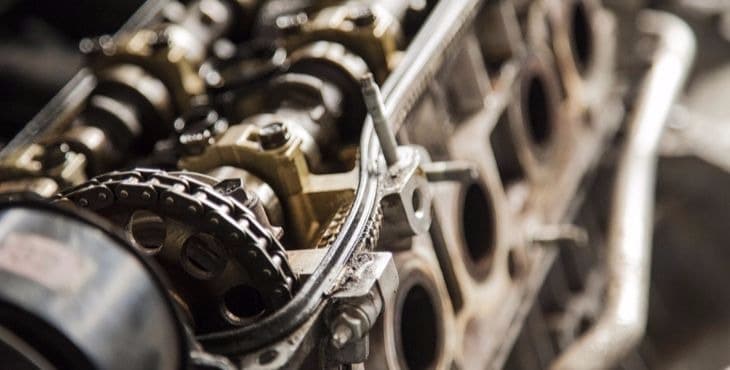

Hydraulic

These are based on the pressure exerted by a liquid – commonly an oil.

Automotive equipment that works with hydraulic actuators achieves greater speed and mechanical strength, and has a large size; it is therefore used in applications where a heavy load is required.

Among the advantages of using hydraulic actuators are the high ratios between power and load, their higher frequency response or their wide range of speeds; in addition to generating more force than a pneumatic system of the same size, for example. As a drawback, the possibility of oil leaks and the need for various additional pieces of equipment (particulate filtering, air elimination or cooling systems) imply a major handicap when deciding on this actuator.

As for its most common applications, hydraulic actuators are used in automotive pumps or engines.

Pneumatic

For its operation, compressed air is connected to one side of the piston or vane, generating a force in the direction of the expansion of the space between the piston and the wall of the cylinder or housing. By means of a mechanical device, the motion becomes rotational. Among its most widespread applications we can mention, for example, engine cylinder systems.

In regard to their advantages, pneumatic actuators are cost-effective in regard to the material, since air is not flammable and can operate regardless of external conditions. Additionally, they avoid overloading and in case of a leak, they are not a safety hazard. However, they work with an expensive and noisy energy source, which demands the prior preparation of the compressed air: elimination of impurities and moisture.

Electric

The structure of an electric actuator is simple when compared to that of hydraulic and pneumatic actuators, since only electric energy is required as an energy source for the actuator. Since they operate using electrical cables in order to relay control signals, they are highly versatile and avoid spatial restrictions between the energy source and the actuator.

There is a significant number of models and it is easy to use them with standardised electric motors depending on the application; even though in most cases it is necessary to use speed reducers, since the motors operate continuously.

Among their many advantages, we can find, as we mentioned before, simple access to energy, and in addition, a faster transmission signal and higher control precision. On the other hand, some of their disadvantages are the possibility of an overheating motor or wear of the speed reducer’s gears.

You might be interested in taking a look at some applications: Main electric actuators in the automotive industry

CLR electric actuators: Audi RS success story

This project started more than a decade ago with the purpose of overcoming a problem the Audi automotive company had at the time. In order to improve their Dynamic Ride Control variable suspension system, Audi’s TIER 1 provider needed to add gear motors that were capable of adjusting the rigidity of the shock absorbers in their hydraulic pressure system, avoiding the use of any electronic controller. Operation would be manual via a button located on the dashboard.

The main problem of this ambitious project was making the designed gear motors function at peak performance, withstanding the high vibration levels of the shock absorber. CLR’s engineering team had to find a compact solution, resistant to the harsh external conditions (water, moisture or snow) and capable of withstanding temperatures over 85 degrees Celsius.

In the end, the actuator fully met the stringent standards governing their application in the automotive sector, as well as the many quality requirements of one of the leading companies in the automotive industry.

At CLR we work every day to offer electric actuators tailored to the needs of your automotive projects. Our extensive experience in the field of vehicle electromechanics enables us to offer solutions that are precise, silent and long-lasting, providing an innovative outlook that is committed with the outcome of your project.

Are you looking for a new component or actuator supplier for the automotive industry? In this complete guide by CLR we give you a few tips for reviewing and selecting your Tier 2 suppliers.