There are many types of geared motors that can be used in search for the perfect movement in an engineering project. Taking into account the technical specifications, the required performance or space limitations of our design, you should ask yourself to use one or the other. In this article we will delve on the planetary gear motors or epicyclical gear, so you will know thoroughly what its advantages are and discover some successful applications.

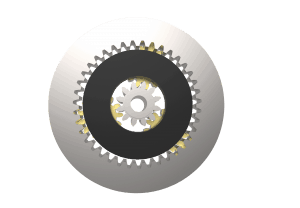

The planetary gear units are characterized by having gears whose disposition is very different from other models such as the uncrowned end, cyclical (step by step) or spur and helical gears. How could we classify their elements?

- Sun: The central gear. It has a larger size and rotates on the central axis.

- The planet carrier: Its objective is to hold up to 3 gears of the same size, which mesh with the sun gear.

- Crown or ring: an outer ring (with teeth on its inner side) meshes with the satellites and contains the whole epicyclical train. In addition, the core can also become a center of rotation for the outer ring, allowing it to easily change directions.

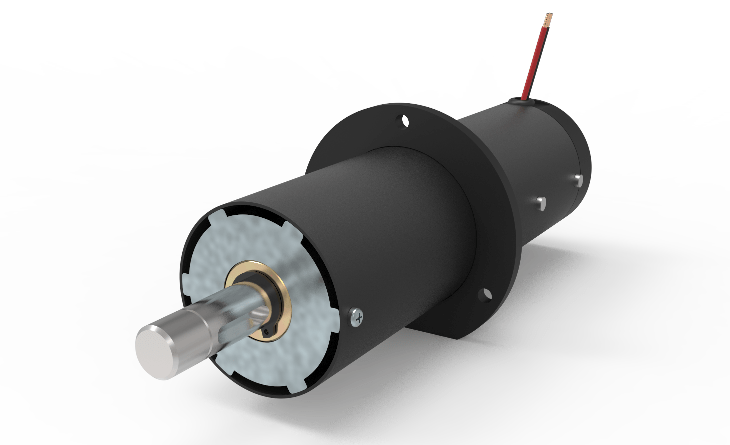

For accuracy and reliability, many automatic transmissions currently use planetary gear motors. If we talk about sectors this reducer offers great versatility and can be used in very different applications. Its cylindrical shape is easily adaptable to an infinite number of spaces, ensuring a large reduction in a very contained space.

Regularly this type of drives can be used in applications that require higher levels of precision. For example: Industrial automation machines, vending machines or robotics.

What are the main advantages of planetary gear motors?

- Increased repeatability: Its greater speed radial and axial load offers reliability and robustness, minimizing the misalignment of the gear. In addition, uniform transmission and low vibrations at different loads provide a perfect repeatability.

- Perfect precision: Most rotating angular stability improves the accuracy and reliability of the movement.

- Lower noise level because there is more surface contact. Rolling is much softer and jumps are virtually nonexistent.

- Greater durability: Due to its torsional rigidity and better rolling. To improve this feature, your bearings help reduce the losses that would occur by rubbing the shaft on the box directly. Thus, greater efficiency of the gear and a much smoother operation is achieved.

- Very good levels of efficiency: Planetary reducers offer greater efficiency and thanks to its design and internal layout losses are minimized during their work. In fact, today, this type of drive mechanisms are those that offer greater efficiency.

- Increased torque transmission: With more teeth in contact, the mechanism is able to transmit and withstand more torque. In addition, it does it in a more uniform manner.

- Maximum versatility: Its mechanism is contained in a cylindrical gearbox, which can be installed in almost any space.

What regulations apply to planetary gearboxes?

Keep in mind that each manufacturer sets its own measures when presenting the operating time of your gears or the maximum torque they are able to bear. Nevertheless, we can find certain regulations governing these parameters.

– ISO 6636 for gears.

– DIN ISO 281: With all the rules that helps to make a correct calculation of the bearings.

– ISO 9409: Part II talks about the design of the output shafts of these geared motors according to different specifications.

Cases of successful implementation of planetary gear units in CLR

CLR has more than 20 years manufacturing planetary gear motors in very different fields. Many of our engineering solutions have brought significant technological and quality in highly specialized sectors advances. You can see two such examples:

- Case 1: A passive fire protection company needed a solution to facilitate the evacuation of people in buildings in case of fire. For this project a system of isolation barriers driven rollers was developed through a planetary gear developed by CLR. It was able to design the perfect motion of falling barriers in extreme situations and with total lack of power supply.

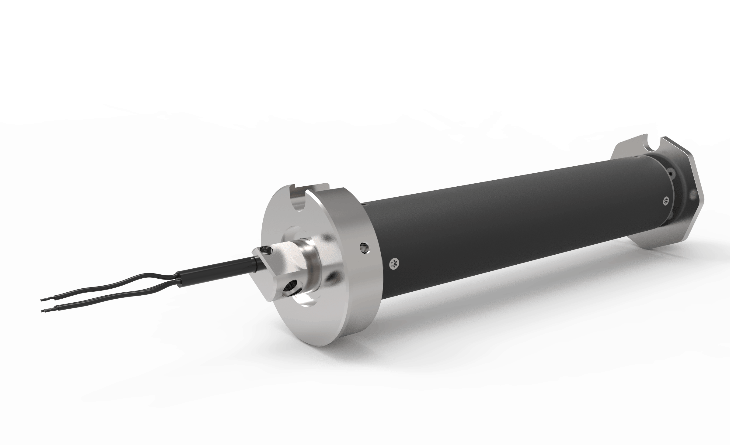

- Case 2: Regulation of ventilation in farms: In this project the air conditioning sector, a system that uses sensors for automatically controlled ventilation inside the farms and greenhouses was designed. CLR developed an epicyclical gear motor that adapted to the difficult tubular location that it would be installed.

The Compañía Levantina de Reductores has a wide range of standard drive solutions standard in its catalog of planetary gear motors; with gears ranging from 4: 1 to 2671: 1. In addition, all models of the CLR brand are modular, since several motors can be mounted on the same gearbox. This feature allows customers to incorporate the ones best suited to their needs.

On the other hand, the CLR engineering department is able to design and produce customized drive solutions for more specific applications that require a comprehensive solution from design to final production applications.

Would you like to know what steps to follow when you have to choose the gear motor that best conforms to your needs? Then you need to download our free guide: “Gear motors: choosing the best one for each project.”

I very glad to find this website on bing, just what I was looking for 😀

besides saved to bookmarks.

Thanks for your comment. We hope you enjoy our next articles. Regards.

Thank you for this information. I’ll add this blog to my list.