Noustique Perfumes was born from a joint venture between 2 large multinational enterprises from different sectors. On the one hand, BSH Group, a German manufacturer of white goods that includes the brands Bosch, Siemens and Balay, among others. On the other hand, Puig, a Catalan company dedicated to the creation of perfumes that comprises brands such as Jean-Paul Gaultier, Paco Rabanne and Carolina Herrera, among others.

This great company has manufactured a perfume creator that allows them to generate their own custom-made perfumes with just a simple and pleasant procedure. The device is called Scent Creator and is marketed under the brand name The Alchemist Atelier. The Scent Creator makes it possible to obtain customized fragrances, which can be adapted to a particular mood, style or special occasion. It also allows you to create personalized gifts, in a very short time and in just minutes.

To ensure that fragrances are tailor-made, users can choose the scents of a 34 essence and adjust the combination to their taste, until they get the one they prefer.

This product works in a very simple manner. First of all, the user needs to choose the essences he or she wants to include in his or her composition. These essences have been developed by expert perfumers using high quality ingredients. As an additional feature, the creators have developed an innovative and intuitive visual language that explains in detail the composition of each of the essences to the user.

Once the choice of the ingredients has been made, the Scent Creator dosing system takes care of creating the customized fragrance. The objective is to refine the personal blend from home or guided by perfumers in 90 minute sessions, which The Alchemist Atelier organizes in its first physical point of sale located in Paris.

Once their creation is complete, users can enjoy the result and also share their personal combination in the growing community creative library of sensational fragrances, available in The Alchemist Atelier application.

Thanks to the implementation of innovative technology, this Scent Creator is able to adapt its products to any home, combining fragrances through a unique application with visualization technology that helps users to learn and explore the world of perfumes, and even to share them.

Objective: to obtain two actuators for the dispenser and to ensure its correct operation

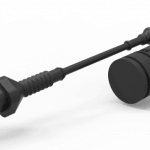

The ‘Scent Creator’ is a device that consists of two main actuators. The first one is a feeder, which is responsible for moving the various essence cartridges that the user has chosen and inserted into the device. The second one is the dispenser, a linear actuator that presses the cartridges so that the essences they contain are extracted.

Noustique Perfumes got in touch with CLR to look for a robust solution in record time.

This might interest you: Electric Actuators in robotics: some surprising innovations

The Challenge: to improve a feeder with a semi-functional and noisy design

The customer supplied a feeder that had a semi-functional design, which was not industrialized and had ample potential for optimization, in order to achieve guaranteed operation throughout its life cycle. Moreover, it was desired to minimize the noise generated by the feeder itself during operation.

The new dispenser was co-developed by CLR and BSH Spain. CLR worked on a solution to solve the problem and to achieve the necessary precision in the output shaft, thanks to the use of a stepper motor.

Recommended reading: How to avoid noise and vibrations in your gearbox

This is how the project was developed

The project was divided into 4 distinct phases:

- A 3D design of the gearboxes was generated to be used to improve the operation of the device.

- The first prototypes with machined and sintered components were manufactured.

- The second prototypes were manufactured, with final materials for approval and CE certification of the final device. These prototypes are made by mechanization and injection in prototype molds.

- The industrialization and pre-series of both actuators was carried out; the product tooling and line tooling necessary to guarantee the maximum quality levels required by the customer were created as well.

The Acoustic Component: a considerable challenge

One of the main challenges in the project with Noustique Perfumes was the acoustic component, since it was of paramount importance to the client. The Scent Creator’s actuators work with continuous intermittence and changes of direction, which results in the permanent generation of sound.

In a domestic context, this can be uncomfortable for the user of the device. On the other hand, the project had the added challenge of being governed by the highest requirements of the white goods sector or SDA (Small Domestic Appliances), both in the production process and in the traceability of the components.

You may also be interested in: The importance of good sound pressure measurement in equipment and machine gearboxes

The Solution: a design customized to meet specific needs

In the search for a solution that would solve the problems posed and satisfy the client’s quality standards, CLR planned and carried out the work with definitive materials in the prototypes. This made it much easier to meet the product’s requirements.

In this way, the actuators were able to work up to 100 times more cycles than initially required by Noustique Perfumes. All this, without presenting any mechanical problem.

What advantages or benefits did the client gain by working with CLR?

The fact that Noustique Perfumes could work with an engineering company that had a production process, as is the case with CLR, allowed it to ensure that the designed product complied with DFMA and was industrializable beyond the prototype phase.

Thanks to the solution developed by CLR, with the help of BSH Spain, Noustique Perfumes obtained a turnkey product with 100% of its mechanisms tested to avoid problems on their assembly lines.

In addition, and most importantly, the possible incidences that the end user of the product had to face have been avoided, since Scent Creator is not conceived to be used in an industrial environment, but in a domestic one. This whole improvement process has been achieved despite working with a very short time frame.

If you need to start your automotive project or have an engineering problem that you don’t know how to solve, feel free to get in touch with us. Our team will design a customized solution capable of meeting needs of your project.