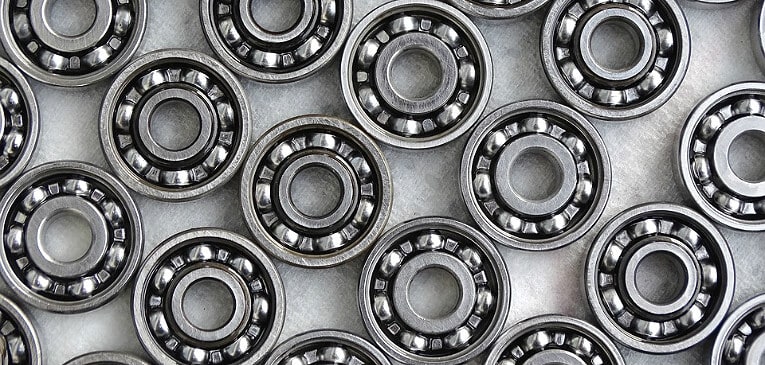

The purpose of rolling bearings is straightforward: to bear radial, axial or combined loads in order to improve the operation of mechanical transmission systems. When it comes to speed reducers, rolling bearings counter these static and dynamic loads, guaranteeing the system’s stability and reliability, and the product’s durability. You may be wondering, what are these loads and how do we calculate them? Which steps should we follow to make a proper rolling bearing calculation?

mechanical components

6 applications of worm screws

One of the main and most widespread transmission mechanisms in any mechanical project. Worm screws stands out do to its simple operation and mechanical advantage. Worms engage with a worm gear in such a way that, for each full rotation of the worm, the worm gear rotates by a single tooth. Therefore, for the worm gear to fully rotate, the worm has to rotate as many times as teeth the worm gear has.

Types of rolling bearings and how to know which one I need in my actuators

In the design of a gear motor or gear box it is paramount to keep in mind several factors in order to fulfil the commercial demands, and those of the application. The mechanism’s efficiency, its noise levels, or its durability and reliability are key factors. With this in mind, selecting the right rolling bearings in each project is of the utmost importance in order to improve the performance and operation of the speed reducer in the machine. But, what types of rolling bearings exist? What do I have to keep in mind in regards to the work of the speed reducer? You will find this article interesting.

What is a servo motor and when is it used?

Selection of an electric motor is fundamental for any electromechanical project. When the project requires maximum precision, it is increasingly common to think about the star of this article: servo motor. Get to know how they work and why they are one of the basic devices in robotics and industrial sectors that require highly precise motions.

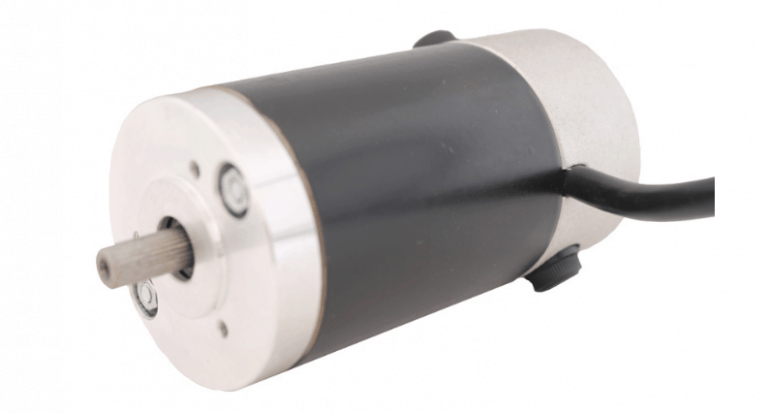

Tips for selecting small electric motors

Selection of the most appropriate electric motor for small applications results from analysing its load requirements for each application, as well as other more specific considerations such as work, system efficiency, motion requirements for the application, or the wear it is subjected to during its daily operation. We bring you some tips for you to select the right small electric motors. Keep reading!

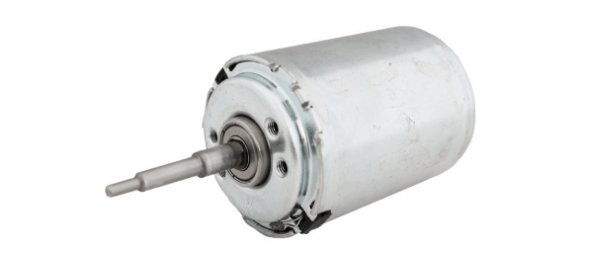

Differences between brushed and brushless motors

When developing an application that requires an electric motor or gear motor to achieve an actuation, it is common for you to ask yourself: brushed motors or brushless motors? The choice will depend on the type of application that we are to develop, its size, and power requirements. The differences between these electric motors are given by their operation and structure. Learn about the specifics of each of them in this article.

Helical gears or spur gears?

Gears are a key component of motor and machinery actuators; they increase the output torque and control the direction of rotation or the speed. CLR –Compañía Levantina de Reductores- has an extensive experience in the manufacturing of plastic and metal gears in many shapes and sizes: spur gears, globoid gears, planetary gears and helical gears; with pinion, bolt, or different types of tooth. Among them, helical and spur gears are usually the most widespread across many industrial applications. Do you want to know their differences and features in-depth? This article can help you.

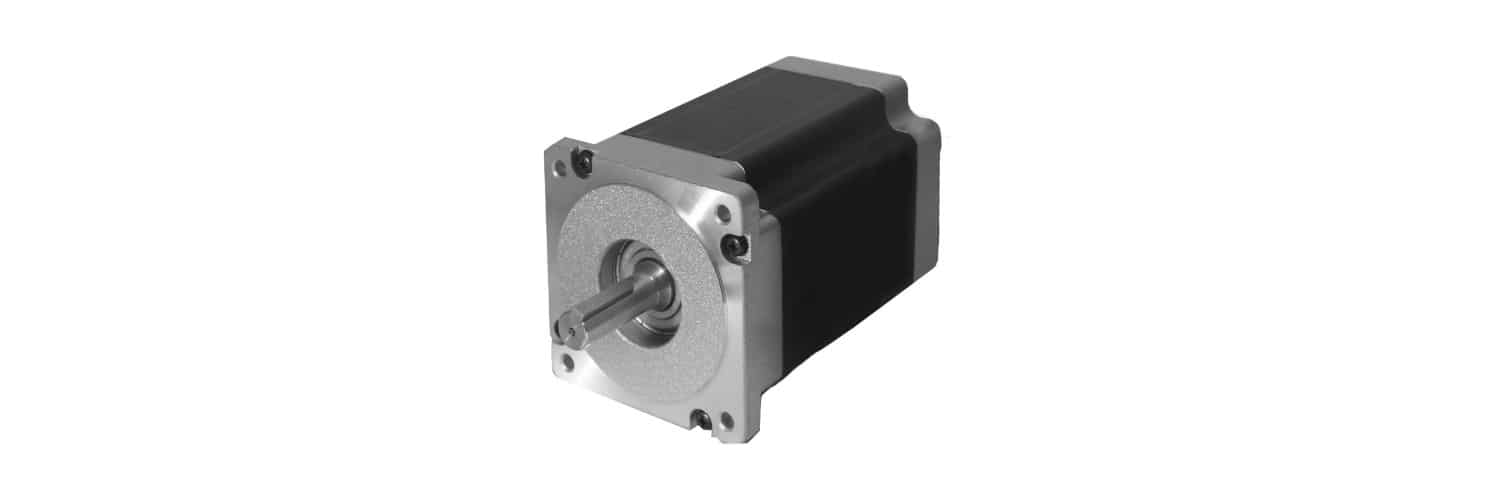

Step motor: When to use it, and why

When undertaking an electromechanical project, selection of the type of motor tends to be one of the most critical aspects for any Project Manager. Depending on the mechanical motion required, there are many solutions that range from universal motors, to step motors and servomotors (for more complex applications). Do you know when a universal motor will be suffice? Do you know under what circumstances you should opt for a step motor? Let’s take it from the start.

“Surface treatments in mechanical components increase gear motor running times by 30%”

The quality of gears and other mechanical components of the gear motor guarantee the best performance under long operation times. CLR Sales Engineer Juan Miguel Navarro acknowledges that in order to achieve such a quality, surface treatments are the added value that turn a good product into the ideal solution to every need. Do you want to find out why? Then pay attention to this interview.