Plain bearings are mechanical components charged with bearing a load and allowing a sliding or rotational motion between two parts of a machine. Their main purpose is preventing wear of the points of support of the machine, which would take place if the shafts were to roll directly on the structure.

Are you involved in a project but knowing which bearings you need is giving you headaches? Don’t worry! In this post we will tell you about its uses and types. Let’s get to it!

Plain bearings are composed of two parts. On one hand, there is the fixed part, which bears the loads, known as the support, and on the other, the area that gets worn; in other words, the one that is in contact with the moving element: the bush.

With the purpose of minimizing the losses generated by the bearing friction, material pairs with low friction coefficient is generally used, or a lubricant is added between the parts: solid – graphite or Teflon -, liquid – oil – or gaseous – pressurized air.

Types of plain bearings

– Depending on the type of contact between the parts:

- Plain or friction bearings

The fixed and moving surfaces have a sliding friction, and are separated by an oil film.

They are also known as bushes, solid bearings and friction bearings, generally have a cylindrical shape and contain no moving parts.

- Rolling bearings

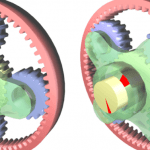

In them, the journal of the shaft and the rolling surface of the support are separated by rolling elements, so that when the journal or the bearing rotates, a rolling motion is generated instead of a sliding one.

They are composed of two rolling rings separated from each other by other equally rolling elements that are located between them, whose shape varies depending on their use.

– Based on the lubrication system employed, there are three basic types of plain bearings:

- Self-lubricating bearings: They require no external lubrication. They are manufactured with porous materials that, when impregnated with oil, absorb it and slowly distribute it throughout the parts in motion in a machine.

- Regularly lubricated bearings: They require a limited periodic lubricant addition.

- Continuously lubricated bearings:

- Hydrostatic bearings: The lubricant is pressure-fed using an external pump. Its main disadvantages are that a failure in the supply of lubricant endangers the installation, and their high cost.

- Hydrodynamic bearings: They do not require an external injection of lubricant, but instead it is the moving parts that generate a hydrodynamic effect which makes oil lubricate the parts that are in contact. These bearings work on their own and do not require an external, pressurized oil feed. Their use is critical in machines that have a high starting torque.

– Based on the position of the rolling bearing in relation to the load, there are three types:

- Axial: Which can take loads in the direction of their shaft.

- Radial: Which take loads perpendicular to their shaft and none longitudinally.

- Thrust: They take both axial and radial loads.

Advantages and disadvantages of plain bearings

Plain bearings have advantages and disadvantages when compared to rolling bearings; some of them are:

Advantages:

- They are lighter.

- Lower costs

- Longer fatigue-free service life of their elements.

- Lighter weight.

- Less noisy.

- They require less radial space, since they are built with thin walls.

- Their installation is simpler.

- Using self-lubricating bearings, lubrication procedures are not required.

- They allow for higher rotational speeds.

- Greater shock resistance.

Disadvantages:

- Higher friction during transient processes (especially during startup).

- They require more axial space.

- The use of friction resistant materials in their manufacturing is indispensable.

- Greater wear when compared to rolling bearings, since there is a direct friction between the bush and the shaft.

In many occasions, rolling bearings perform the same functions than plain bearings, but the selection of one or the other in a project depends on the end use they may be given.

In one of its success stories, CLR’s team decided to use plain bearings, since they exceeded the mechanical requirements for the equipment and allowed for a cheaper shaft rotation, being the best solution, and the most beneficial for its customer.

This is the reason why, when choosing your component supplier, you should keep a number of factors in mind, such as the professionalism and quality of its team, without forgetting about its reliability and zeal, two fundamental aspects in order to lead your projects to success.

WoW !! Its Was So beautiful To reading !! I Have learn so many things from this site!! As a mechanical Engineer .. i just give you Thank you !!