Are you interested in the world of rapid prototyping? The use of rapid part prototyping is nowadays widespread in industries such as automotive and aeronautics. Its purpose? To generate an exact three-dimensional replica of complex parts by using 3D CAD applications. In this article we will go over various techniques to manufacture prototypes, with a special focus on the advantages and limitations of 3D printing.

Technology

Multi-material injection moulding: main techniques and advantages

Multi-material injection moulding (overinjection) is one of the most widespread technologies for manufacturing plastic components. The process is based on the injection of two or more materials in a single mould and process. In this article we will analyse its various techniques as well as the advantages it can offer for the production of personalised parts.

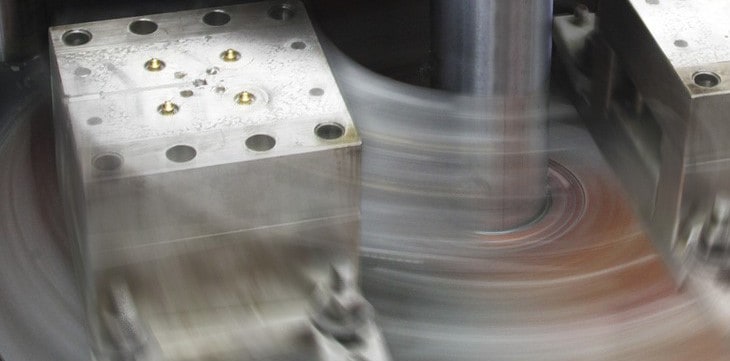

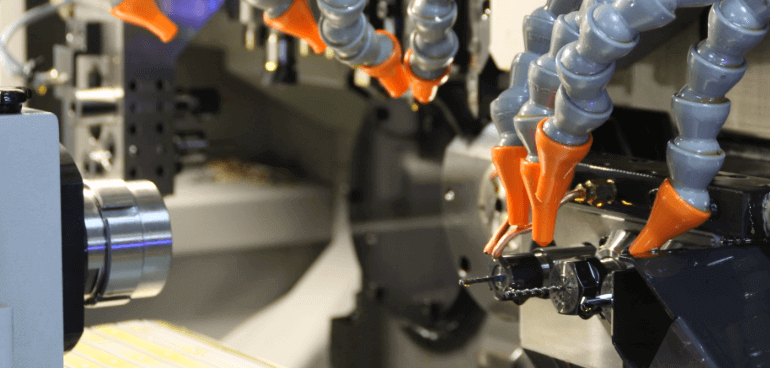

5 innovating machining processes you may not know about

Up until today, traditional precision machining processes were at the forefront of the industry. Nowadays, new machining processes have emerged with the purpose of overcoming precision errors, improving energy efficiency and limiting the generation of pollutants. In this article you will learn about the new trends in machining techniques.

Plastic Injection Moulding: new technologies and applications

Injection moulding is a technique used for manufacturing various mechanical components. The versatility of this method enables the high quality, low-cost, rapid manufacturing of plastic parts. Would you like to know what the latest plastic injection moulding technologies are? Do not miss this article.

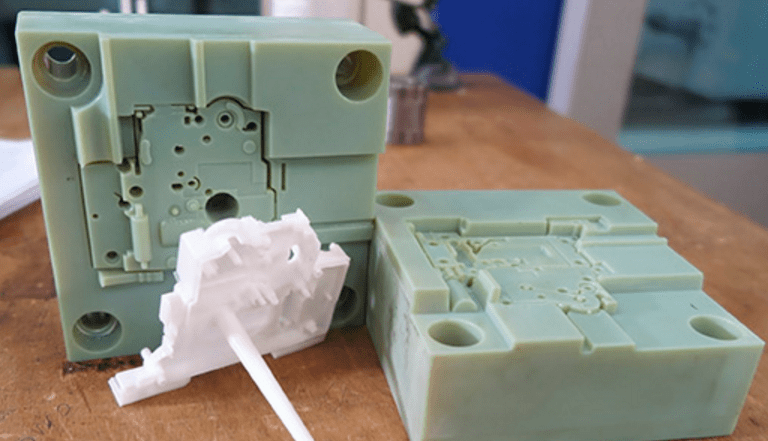

3D printed injection moulds: advantages and limitations

The use of 3D printing for manufacturing injection moulds allows for prototypes to be made quickly and with high precision. The purpose of this system is accelerating and perfecting the design of the final part before mass production. In this article we analyse the advantages and disadvantages of this revolutionary system which is gradually being adopted by mechanical component manufacturing companies. Let’s begin.

Precision machining: the road towards the perfect component

On any mechanism, even the smallest part may influence daily operation of a machine. When referring to machining of all those items, the technology and quality of the machining centre is a key factor. It is for this reason that investing on the latest in CNC (Computer Numeric Control) lathes is the best bet for obtaining components of the highest precision and reliability for very specific purposes. Do you want to learn more about precision machining? Are you in doubt when selecting machining companies? Then don’t miss this article.