What would be the point of having a security device whose parts are incapable of dealing with flames? To what extent would we be referring to “security”? One of the basic characteristics that make a device reliable and sturdy is the material it is manufactured with being adequate, and for it to comply with the specifications, regulations or certifications of each sector. In the case of the security sector, this point cannot be disregarded, since the work involves components that are the target of theft and other damages. Fireproof plastics are an example of this. Below we tell you about the ones that stand out from the rest.

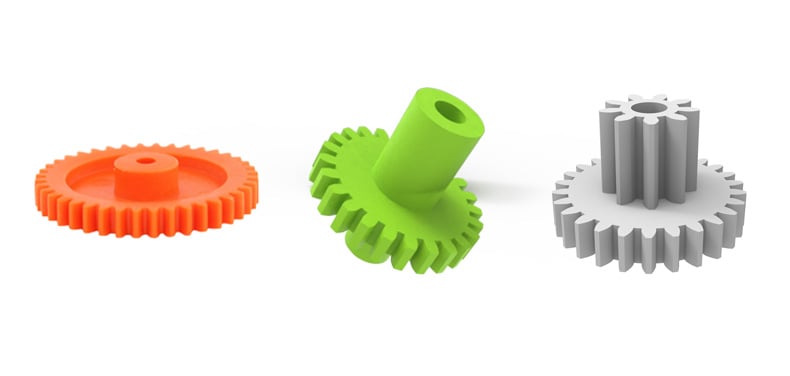

A myriad of small components, such as gears, washers, bolts, pinions or screws are involved in speed reducers. For this reason, it is vitally important for all of them to be manufactured with the most sturdy materials in order to prevent a rapid wear, overheating affecting their performance, or even to guarantee a fast flame extinction – fire retardant or fireproof materials.

Would you like to improve your security mechanisms with self-extinguishing plastics? You are one step away from learning about the regulations affecting plastic flammability and their self-extinguishing levels. Let’s get down to it!

The use of fireproof plastics has a growing importance worldwide due to the replacement of many metallic parts for plastic equivalents. Any UL-certified plastic has a self-extinguishing classification. For example, an application where this property is highly important are ATMs or cash dispensers, in this way, vandalism is prevented, since having plastics with self-extinguishing properties prevents the propagation of fire and makes it harder to steal the money they contain.

Underwriters Laboratories is an independent organisation that offers product safety tests and certifications. Their UL94 testing procedures ant the classification system to determine the flammability of thermoplastics and silicones are a standard that is generally accepted worldwide.

Different type of UL certifications

This test measures the burn time of a vertically fixed polymer sample after it has been in contact with the flame of a Bunsen burner during 10 seconds. V0, V1 and V2 tests determine the self-extinguishing degree of a polymer:

- As per the UL 94 (Vertical Burn) V0 Classification: The fire is extinguished in 10 seconds with no dripping.

- As per the UL 94 (Vertical Burn) V1 Classification: The fire is extinguished in 30 seconds with no dripping.

- As per the UL 94 (Vertical Burn) V2 Classification: The fire is extinguished in 30 seconds with dripping.

It is important to use a UL 94 V0 grade certified material due to the high level of safety it offers, since it possesses the best self-extinguishing properties and minimises fire hazards.

This test measures the burn time of a horizontally fixed plastic sample after it has been in contact with the flame of a Bunsen burner for 30 seconds. According to UL 94 HB, a material is classified as HB when a sample with a thickness of 3mm burns at a maximum speed of 76mm/minute.

UL VW-1

The purpose of the UL VW-1 Vertical Wire Flame Test is to classify the flammability of cables and hoses.

The UL VW-1 test uses a Tirrill as an ignition source. A flame is applied to the sample for 15 seconds and then withdrawn. A flame is applied to the sample for 15 seconds or when the sample is extinguished, up to a total of 5 15-second applications. If the sample passes this test, this confirms that it should burn no longer than one minute.

Pay attention to these pure materials:

Performance of plastics exposed to flames:

- Highly combustible plastics: PS, PMMA, CA.

- Combustible plastics: PE, PP, SAN, ABS, PET, PBT, POM, PA, PUR.

- Mildly combustible plastics: EP.

- Self-extinguishing plastics: PVC, PC, PPE, MF, PSU, PI.

- Non-combustible plastics: PEEK, LPC, PTFE and fluoroplastics.

A security project leaves no room for error, which is why it is paramount to work with a supplier that is capable of guaranteeing compliance with the highest standards and certifications.

At CLR, our team of engineers works every day with the goal of finding the best solution in automatic locks, safety locks, security barriers and smart locks, among other projects. Compañía Levantina de Reductores works as a partner that is committed to your project and with obtaining the best results in regard to performance, reliability and security. Do you need help with a new project? Our experienced team can help you improve the safety of your actuators. Contact us and find out for yourself!