After telling you about the differences between bushed and brushless motors, we address in detail one of the aspects that limit the most the design of a small actuation solution: the selection of direct current motors (DC motors) and alternating current motors (AC motors). Depending on our drive requirements (speed/rpm, starting torque, power, torque/Lb-Ft, etc.) and the characteristics of each of these motors, we will opt for one or the other. We hope you find our advice useful.

Classification of DC motors and AC motors

First, we will focus on the various options you will find when looking for electric motors:

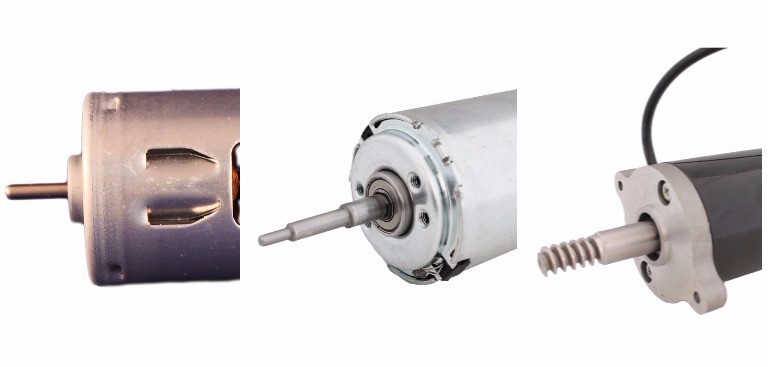

Direct current motors (DC motors)

These motors are classified based on the way their inductor coils are connected.

Here we can find:

- Separately excited motor

- Series-wound motor

- Shunt-wound motor

- Compound motor

Alternating current motors (AC motors)

Their classification is based on their rotation speed, number of input phases and the type of rotor.

Based on their rotational speed, they may be classified as:

- Synchronous

- Asynchronous

Based on the number of input phases:

- Single-phase:

- Three-phase:

- Two-phase

Based on the type of rotor:

- Slip-ring motors

- Collector motors

- Squirrel cage motors

What are the most important aspects when choosing DC or AC motors?

Before a purchase manager begins the task of choosing electric motors for a project, he should be well aware of the main specifications of the application. These specifications are:

Type of start-up

We should analyse the amount and characteristics of start-ups. There are machines that require a starting power that a motor may not be able to provide.

Load

Here we will consider its operation with or without a load. When bearing a load, the motor is dragging an object or bearing an external resistance (the load) which forces it to absorb mechanical energy. Therefore, in this case, the torque resistance results from internal and external factors. When a motor operates without a load, it does not pull any object, neither does it bear any sort of external resistance. The shaft rotates freely and any resistance results from internal factors.

Torque

This information specifies the motor’s driving ability. This parameter will be key on any application where we intend to create a motion or displacement.

You will find this article interesting: “Power and torque: what are they and what is their difference?”

Electrical power used by the motor (in kW)

When efficiency is a key factor for your project, you should calculate the electrical power used by the motor during its operation.

Performance

You should analyse energy losses on the motor resulting from external (humidity, ambient temperature, material properties, etc.) and internal (material properties, brushed or brushless motors) factors.

Variations in, and progression of, the rotational speed

There are many aspects that may condition the rotational speed. If our application needs to work at various speeds, we should choose actuation solutions that are highly versatile.

Learn how to improve your DC and AC motor selection skills with this basic guide.

What are the applications of AC motors?

- If we intend to vary the rotational speed, we will need to have a frequency converter, which makes the selection process harder.

- They are suitable for projects where a stable motion and fixed speed are not required.

- They are not suitable for applications that require very low speeds.

- If your application demands the highest performance and torque output, alternating current motors will be a good choice.

- Their price is another factor that may prompt you to choose this solution. Since their manufacturing is simpler, the price of these motors is lower than that of DC motors.

- Lastly, another aspect that sets them apart is that they may be single-phase and three-phase, while DC motors are only single-phase.

Application example

Industrial machinery such as thread winding machines. These applications require a continuous motion and low torque. Since industrial currents are used, alternating current motors are chosen in order to simplify this type of machinery, resulting in the use of less components.

When is it advisable to choose DC motors?

- Applications that require great torque when starting the motor. Thanks to their high starting torque, DC motors are more than fitting. Since their torque is high, they overcome the inertia that may be exerted by the load to be moved during start-up.

- Whenever you require versatility. Using external applications using control electronics, it is possible to modify their current to decrease or increase the output torque and rotational speed. On the other hand, they offer good results both in low and high power applications.

- In cases where you need to power parts, machinery or devices that vary their power during operation.

- In projects where the load is more important than motion precision, these motors may offer you better results.

Application example

Window opening in farms, a successful deployment by CLR related to technologies which improve productivity in the livestock industry.

This project requires a high starting torque to start the motion of the window. The motion is controlled using electronic circuit boards in order to open them at a greater or lesser angle depending on the temperature.

Discover Mootio, CLR’s electric motor online store

Use of AC motors or DC motors in speed reducers

The selection of AC motors or DC motors is one of the most critical processes when designing and calculating an electromechanical actuation solution. Therefore, if you are in charge of a project of this kind, it is important that you are advised and assisted by gear motor manufacturers such as CLR. Their experience can be dedicated to your project, looking for a solution that offers the best performance, reliability and precision: 12V motor, 24v motor, step motor…

More specifically, CLR manufactures gear custom motors all the way from design to manufacturing, dealing with anything that may be related to the industrialisation process. Thanks to engineering team composed of highly skilled Project Managers and mechanical engineers, the company has a significant know how to offer each client and each project.

In fact, CLR has a basic guide that will help you with the task of choosing motors for small drives with the purpose of transferring this knowledge. Download it by clicking on the image.

It is the latest for everyone you have share the great post and helpful for everyone. it is the advanced technology and it will to much help for everyone

thanks