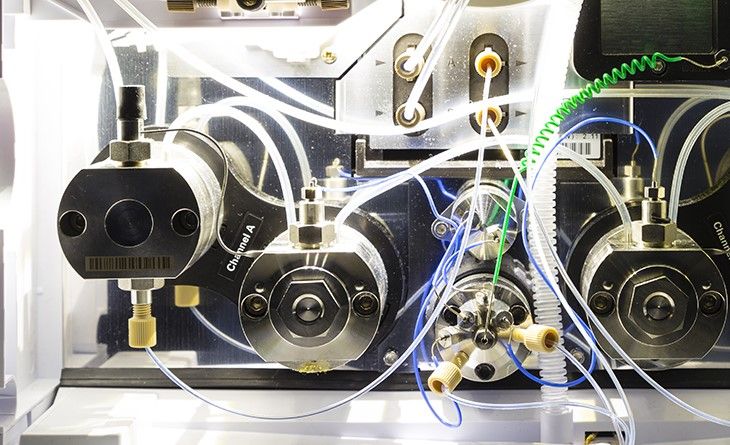

| Peristaltic pump gear |

The leading company in the hygiene and industrial chemical treatment sector relied on our team of engineers to improve the functioning of the gear motor so far used. With the new system, they sought to optimize the performance of their peristaltic pumps responsible for distributing and dispensing their fluids products without altering or having direct contact with the machines. Our solution achieved such positive results that we have adapted the system to other types of mechanisms with the same effectiveness. |

| Problem: |

Although they already had a drive solution for their machines, they contacted CLR to improve the design, performance and quality of their gear motors. For this company, it was important to reduce the cost and the noise of their peristaltic pumps as well as to increase the operating hours of their gearboxes, which were not giving the desired results. |

| Solution: |

Thanks to the research carried out by our team, we found a solution that exceeded the customer’s expectations. Through the use of new materials and heat treatments, we managed to improve the mechanical properties of materials achieving:

|

| Find a tailor-made solution |

| How can we help you? Contact our team of engineers with no obligation. We analyze your needs and advise you on our tailor-made solutions. |

|

Thermal magnetic and differential automatic resetting

Our client relied on us to find a reliable and high quality gear motor that could be installed on a DIN rail.

|