CLR has been providing for over a decade a drive solution capable of regulating the hardness of the shock absorbers of the Dynamic Ride variable suspension system of Audi RS. A system that allows you to change the operation of the shock absorbers according to different driving conditions.

This project started when the company providing the shock absorbing system of the Audi RS6 (company that works with 25% of the vehicles of the planet), contacted from Japan with a very interesting project under their arm. Specifically, the Japanese company needed a drive that gave complete freedom to the driver to regulate the strength of the shock absorbers of the vehicle; avoiding the use of any type of electronic control.

What are the characteristics of the Dynamic Ride Control suspension system of Audi?

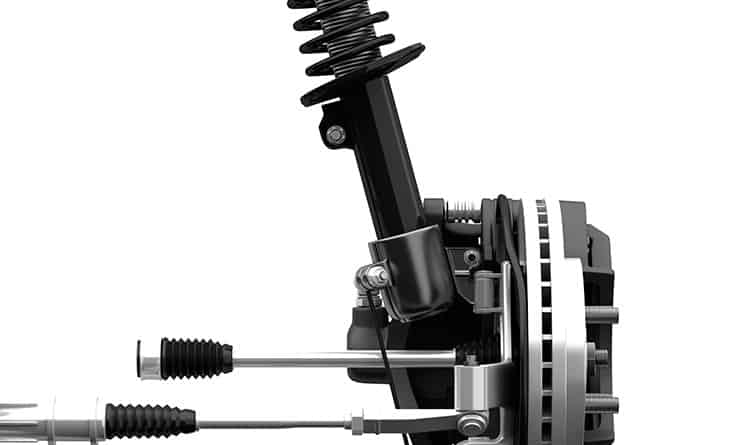

Unlike the vehicles that use steel anti-roll bars to contain body sway, the Dinamic Ride Control System (DRC) is an adaptive suspension system that uses the movement of oil flows inside the shock absorber to counteract the G forces.

The suspension system regulates the flow of oil through several valves. Thus, once the vehicle begins braking, the flow to the front wheels increases. In this way, the support is improved and the body inclination toward the front is reduced.

To complete the system, the supplier company TIER 1 of Audi needed to incorporate gear motors capable of regulating the hardness of the shock absorbers of the hydraulic system, based on a three stages variable. The ultimate goal was to achieve a more comfortable and personalized driving, that offered the driver up to 3 choices of driving more or less sport.

What were the principal problems of the project?

The main problem of this ambitious project was getting gear motors capables to work at peak performance, supporting high volumes of vibration of the interior of the shock absorbing system inside the vehicle.

It was a real challenge for our engineering team since they had to look for a solution that was compact, resistant to harsh external conditions (water, snow or moisture) and able to withstand heat spikes of more than 50 degrees.

On the other hand, the project had another important limitation, the location and limited design volume raised by the customers for the variable suspension system.

What was the solution given by CLR for this variable suspension system?

The team of experts in automotive engineering of CLR was able to design a solution fully adapted to the needs of the project. On the one hand, our gear motor completely adapted to the different regulations governing the incorporation of gear motors in automotive mechanics; as well as numerous quality requirements of one of the leading companies in the automotive sector.

After performing various tests of vibration and heat dissipation, our drive solution was able to overcome with note the performance requirements demanded by the customer; making a customized solution and also adapted to the dimensions conditioned by design.

The results of the new variable shock absorbing system launched by the RS6 model were a success. In fact, the German high range vehicle company adapted the Dynamic Drive Control system to all its RS range. Now our automotive components are present in everyday driving of hundreds of thousands of people around the world. Pride and motivation to keep working.

In CLR we work every day to provide the perfect drive for your ideas. Our extensive experience in the field of electromechanical and automotive vehicles allows us to work with complete safety assuming any new project presented in the table.

Are you looking for a drive solution for your automotive engineering project? Download now our free guide “Gear motors: Choose the right one for each project” and learn to always choose the gear that best suits your needs.