A Spanish company of the physical therapy sector contacted us to solve their problems related to the supply of gear motors for the manufacturing of magnet therapy equipment. They needed a supplier that could meet specific technical specifications while enabling them to obtain a certain number of gear motors.

Objective: meet the acquisition and technological requirements

One of the main issues that the company representatives referenced was their need to acquire a small number of gear motors for the operation of their machines, which would be specifically designed for the manufacturing of a particular magnet therapy machine used in physical therapy treatments. They need to purchase a lower number of gear motors than most suppliers establish as a minimum purchase.

The other objective was to have a gear motor that would be capable of meeting the speed and torque requirements for moving the carriage of the machine. The device has four wheels, an aluminum bed with automated solenoid motion and four independent channels.

You might be interested in: All you need to know about gear motors and their components

The challenge of controlling output signals

The main problem that we faced when addressing the needs of this client was the variability of the encoder signals.

Encoders generate a number of signals based on the system’s precision. Interferences caused by magnetic fields, or even the dirt that affects the sensors of the optical encoders, can lead to variations and failures in the transmission of signals. If this happens, the machine will not be at the right position to effectively activate its various operation programs.

Therefore, meeting these technical specifications and offering the company the right gear motor to address their specific needs were two of the main challenges that were faced by CLR.

The right solution: CLR’s 90º standard model

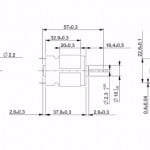

The client was looking for a gear motor that would meet the speed and torque requirements of their new machine for magnet therapy equipment. After studying our product catalogue, they opted for the 90º standard model – a worm drive operated direct current gear motor that has the following characteristics:

- Steel output shaft

- Sintered bush output bearing

- Maximum radial load at 10 mm from the flange: 200 N.

- Maximum thrust load: 80 N.

- Gear material: bronze and steel.

- Aluminum housing

The client was provided with a standard device that had these characteristics, offering the highest flexibility. This was possible because we are a national supplier, and an SME.

Recommended reading: Problems when using oversized or undersized geared motors

Meeting the client’s expectations

At CLR we are aware that our clients expect us to meet their needs, always adapting to their specific requirements.

In this case, we specially made use of our flexibility when undertaking the project. In addition, we opted to eliminate the minimum purchase limits imposed by other suppliers, which were impossible to work with for them.Our staff applies its experience and know-how to all of its projects. The fact that they have been manufacturing gear motors for 50 years allows CLR to be capable of creating the best actuation solutions for each client. This means that if you are having problems when starting a project, you can contact us and let us help you.