One of the leading companies in the field of electromechanical engineering, with a track record of over 60 years in design, manufacturing and sales, had a large alternating current residual current device.

With the objective of minimizing the cost of a component of the circuit board, they considered reducing its size and modifying it so that it would use direct current. To accomplish this, they decided to rely on CLR, who studied their case and offered them a reliable and cost-effective solution.

Would you like to know more about this job? Keep reading! And don’t miss the main challenges we faced and how we addressed them.

Main challenge of this electromechanical project

The main issue was finding a new motor that would work at 220 V, direct current, that offered certain mechanical characteristics in a very reduced space, and that would include a number of detection systems to control de angular position of the control switch.

How was the project carried out?

Once the client contacted us for assistance, we arranged a meeting with them at their facilities to gather the requirements.

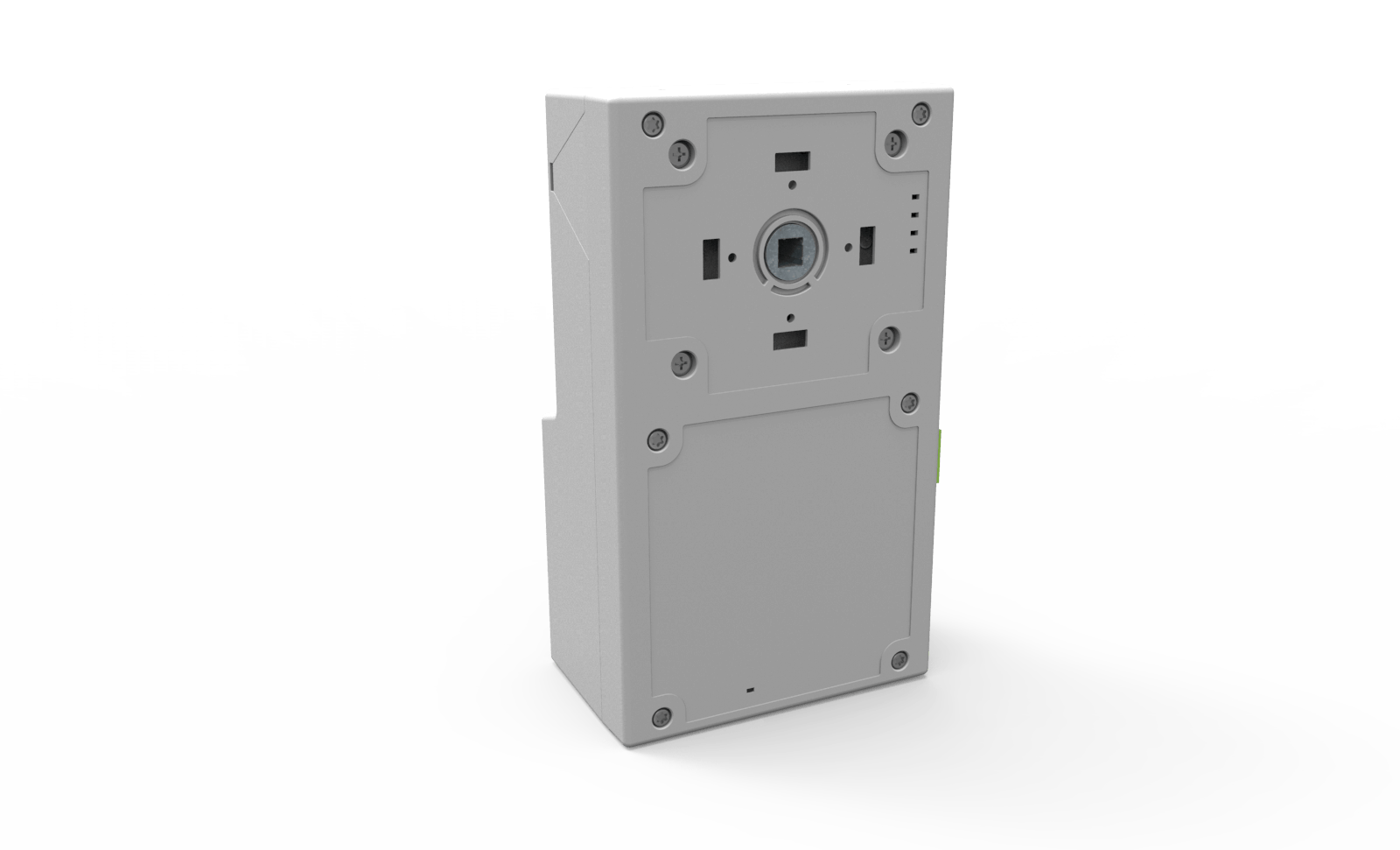

After studying their case, we proposed a product and provided a quotation for the development and the project. After it was accepted by the client, we got started with the design and manufacturing of a working prototype, and once it was completed, we brought it to them in order to find out what adjustments and modifications were necessary for its approval. Once all the modifications requested by the client were completed, we started working on the product’s industrialization and the design of the molds and tooling necessary for its mass production. Once the molds and tooling were completed, we started the first pre-series batch and delivered the client the first samples for final approval.

Why you can trust CLR

At CLR we have been manufacturing gear motors and actuator solutions for over 40 years. Our team of engineers works daily to find great solutions in the smallest sizes, as per the most stringent European Union safety standards.

Furthermore, not only do we specialize in electromechanics, but we also work on projects for sectors such as automotive, vending, HVAC, security and HORECA.

If you need to take on a project or have an issue that you don’t know how to solve, do not hesitate to contact us. Our experienced team will be thrilled to provide guidance and assistance.