One aspect vending machine manufacturers focus on is the noise caused by the mechanisms that delivers the product to the customer. How can these annoyances be limited? What causes this issue? We tell you why it is important to work with high quality speed reducers on each vending machine.

Considering many vending machines are located next to work spaces, conference rooms and waiting rooms, studying the noise level of these machines while operating is vital to guarantee quality and an optimal performance in its daily operation.

These noises are usually the result of the functioning of the speed reducer which actuates the product dispenser in the case of conventional vending machines. For coffee vending machines, the noise is related to the speed reducers that open the coffee, water or milk reservoir for preparing and dispensing the product selected.

Have you wondered how to improve this issue in your machines? The problem is that, in many cases, standard solutions offered by many suppliers do not suffice. Here we offer you a few tips.

What aspects should a vending machine manufacturer control to prevent excess noise?

There are no standardised guidelines that govern actuation solutions for vending machines beyond the specifications described in manufacturers’ quality manuals. For this reason, we will consider the following aspects related to the gear motor’s operation:

Maximum decibel (dB) level during operation

In many cases, the consumer expects there a mechanical noise when inserting his coin and waiting for a product. Still, we should maintain a range that is between 40 – 50 dB. This is a noise level that can be compared to a normal conversation.

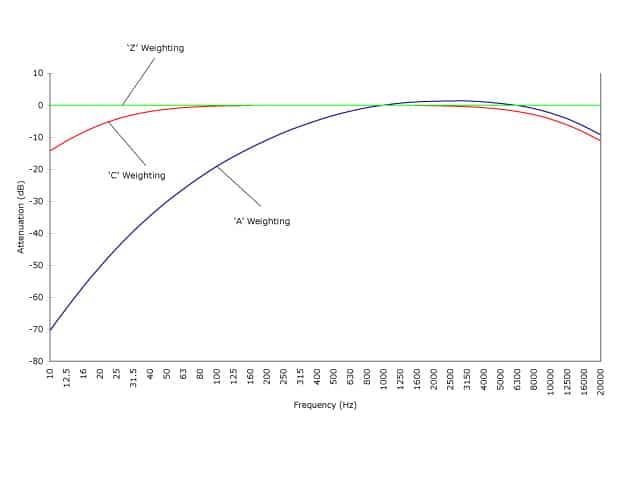

Frequency ranges

Maintained by the speed reducer during its normal duty cycle. Sound level meters allow for studying frequency weightings in a range from A to Z. This is important, since the dB level is not the only aspect that may be annoying to the end user. It is important to keep in mind that human ears may be more or less sensitive to a frequency range. In fact, these levels should be considered and weighed following different measuring criteria.

‘A’ weighting example

‘A’ weighting is the standard of audible frequencies that reflects the response of the human ear to certain frequency ranges that are irritating. These are the medium frequencies: between 500 Hz and 6 kHz.

It is important for your gear motor supplier to have frequency spectrometers in order to measure the different frequency ranges emitted by the vending machine.

Service life or durability test details

Considering the high levels of work performed by these machines, the tests performed in the laboratory, such as vibration analyses, need to be documented in reports that clearly specify the speed reducer’s limits, and under which cases or circumstances its operation may be hindered. Thanks to these tests, the manufacturer avoids unpleasant surprises and can offer a better speed reducer performance during peak machine workloads.

Details regarding the quality of the materials and treatments used

Suppliers should provide information regarding the surface treatments undergone by the various components of the speed reducer. For example, thermal treatments may improve heat dissipation and friction levels, allowing for cleaner and smoother engagements and transmissions.

You will find this article interesting: “Actuators in vending machines: tips to avoid mistakes”

CLR’s testing laboratory studies each operational aspect of speed reducers, testing their limits and all of their specifications. In addition, once the product passes the company’s quality tests, an engineer verifies its operation in the client’s machine.

Have you received complaints by a client related to your vending machines’ noise levels? CLR not only offer turnkey gear motors; we also design customized solutions to satisfy our clients needs. Come see the advantages of purchasing CLR’s speed reducers!

For more information, we are offering you a resource that may help you when selecting the best gear motors for your vending projects. You can download it for free!