What are mechanical vibrations?

Mechanical vibrations can be defined as the movement of a solid body around an balance position. If the vibrating object comes into contact with any part of the human body, it transmits the energy generated by the vibration. This energy is absorbed by the body and can produce in it various effects that depend on the characteristics of the vibration.

They are some of the issues that haunt manufacturers of all types of industrial machines. These, along with undesired noises, affect customer satisfaction and limit the perception and quality of the end product. Would you like to know a few tips to prevent vibrations? In this article-guide we let you know what part speed reducers and mechanical transmissions play in this, and which steps we should follow in order to prevent these problems.

When speaking of machines we can find, for the most part, two sources of noise: those emitted by the motor and those that do from the gears. Both sources act similarly, generating aerial noise and transmitting vibrations to the speed reducer’s structure.

In the case of the kinematic chain vibrations are produced by the contact between the gear teeth as they move, which generates a noise that is transmitted through the air and, at the same time, a vibration that reaches the speed reducer’s housing through various transfer paths.

In speed reducers and transmissions, the noises may result from a defect in the gear teeth due to breakage or excessive wear. This phenomenon causes a mostly non-continuous noise, with varying rattling and signal modulation that can result highly annoying and affect the product’s service life. On the other hand, the speed reducer’s installation in the final solution may also result in significant noises and vibrations. This is why it is recommended to install devices properly, which is to say, adding insulating material whenever possible to act on the transmission path of the vibrations and thereby reduce their effect.

How to prevent mechanical vibrations

In order to reduce the noise generated by the speed reducer, whether due to acoustic vibrations or aerial propagation, an adequate design of all of the components is paramount.

Some tips to prevent these vibrations are:

- Guarantee proper gear operation.

- Maximise engagement rigidity.

- Reduce the transmission error.

- Use helical gears, since they guarantee a greater contact between the gears and reduces the generated noise.

- Use materials with internal damping.

- Study the final speed reducer configuration, especially the housing, studying the possible ways in which the structure may vibrate and preventing resonances.

- Know the final application and design for it taking into account the speed reducer’s characteristics.

You might be interested in: “Spur or helical gears?”

Causes of mechanical vibrations

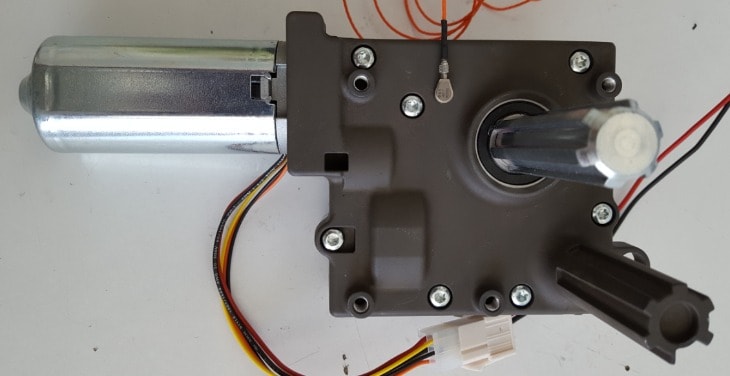

One of the causes why undesired vibrations or sounds are generated in actuator projects results from the use of speed reducers that have not been designed for the housing to which they are attached in the final solution.

In order to prevent these issues, CLR, Compañía Levantina de Reductores, carefully analyses all of the components of the speed reducer, thinking at all times about the client’s final application. Likewise, tests are performed on the gears in order to guarantee that the manufacturing dimensions are accurate, and their finishing is analysed in order to guarantee a low transmission error. Existing vibrations on the housing and supports are also studied, in addition to the aerial noise generated by the device.

CLR relies on development and innovation in sound quality, since it uses the best technology to analyse vibrations and make the right decision on each project.

Specifically, CLR has several accelerometers that analyse the vibrations caused by its products. These types of transducers, in conjunction with a National Instrument measuring system, programmable by using the Labview application, allows for the development of custom-tailored applications adapted to each case.

At Compañía Levantina de Reductores we have been working daily for four decades in order to find the perfect motion for our clients; our goal is to attain high precision speed reducers and components that are able to adapt to small spaces and meet all quality standards, including those related to maximum vibration levels. Are you worried about the stability of your machines or equipment? At CLR we offer you the actuator solutions you need. Contact our engineers!