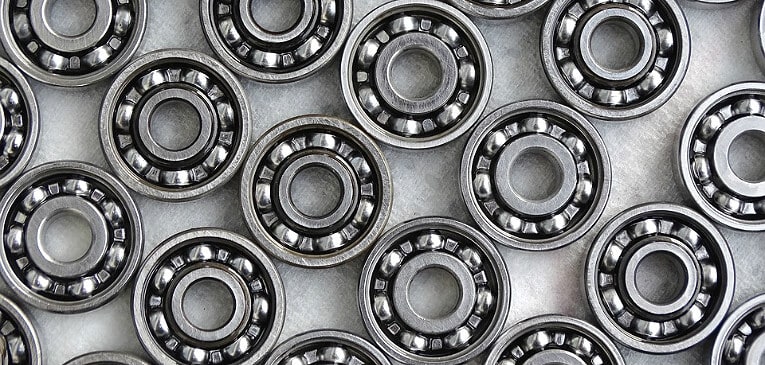

The purpose of rolling bearings is straightforward: to bear radial, axial or combined loads in order to improve the operation of mechanical transmission systems. When it comes to speed reducers, rolling bearings counter these static and dynamic loads, guaranteeing the system’s stability and reliability, and the product’s durability. You may be wondering, what are these loads and how do we calculate them? Which steps should we follow to make a proper rolling bearing calculation?

Month: March 2017

6 applications of worm screws

One of the main and most widespread transmission mechanisms in any mechanical project. Worm screws stands out do to its simple operation and mechanical advantage. Worms engage with a worm gear in such a way that, for each full rotation of the worm, the worm gear rotates by a single tooth. Therefore, for the worm gear to fully rotate, the worm has to rotate as many times as teeth the worm gear has.

Success story: Coin-operated locks for supermarket carts

Over 20 years ago, HiperSystem S.L, a leading company in the manufacturing and distribution of commercial equipment contacts CLR with a very specific need: redesigning and improving their coin-operated locks for supermarket carts.

CLR receives funding for the internationalization of the company, and gets sponsored by the European Regional Development Fund ERDF

Compañía Levantina de Reductores, with its sights set on growing and evolving within the current market, has designed an internationalisation plan that is sponsored by the ERDF Fund.

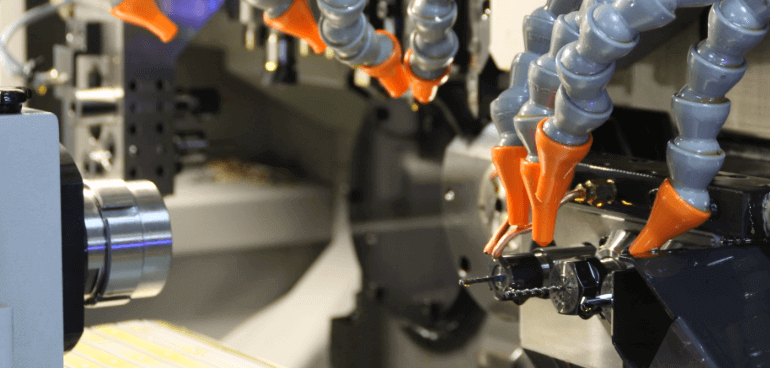

Multi-material injection moulding: main techniques and advantages

Multi-material injection moulding (overinjection) is one of the most widespread technologies for manufacturing plastic components. The process is based on the injection of two or more materials in a single mould and process. In this article we will analyse its various techniques as well as the advantages it can offer for the production of personalised parts.

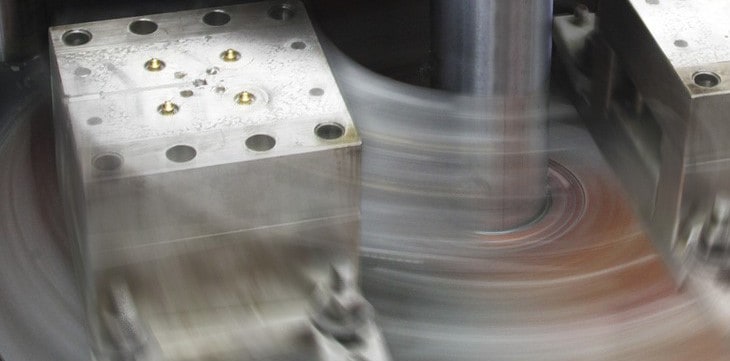

5 innovating machining processes you may not know about

Up until today, traditional precision machining processes were at the forefront of the industry. Nowadays, new machining processes have emerged with the purpose of overcoming precision errors, improving energy efficiency and limiting the generation of pollutants. In this article you will learn about the new trends in machining techniques.

Preventing irritating noises and frequencies in a vending machine

One aspect vending machine manufacturers focus on is the noise caused by the mechanisms that delivers the product to the customer. How can these annoyances be limited? What causes this issue? We tell you why it is important to work with high quality speed reducers on each vending machine.

Main challenges of industry 4.0 today

The impact of technology’s influence, new devices and new forms of communication, has not only affected the private scenery; it is also revolutionising industry with each passing day. No one can escape the industry 4.0 concept – a term that references the application of digital technologies in the industrial production chain. And that is because nowadays, industrial processes demand a high connectivity between all of their processes. But are we prepared to keep up with this technological evolution? Where would we set the boundaries for SMEs? You will find this article interesting.

Types of rolling bearings and how to know which one I need in my actuators

In the design of a gear motor or gear box it is paramount to keep in mind several factors in order to fulfil the commercial demands, and those of the application. The mechanism’s efficiency, its noise levels, or its durability and reliability are key factors. With this in mind, selecting the right rolling bearings in each project is of the utmost importance in order to improve the performance and operation of the speed reducer in the machine. But, what types of rolling bearings exist? What do I have to keep in mind in regards to the work of the speed reducer? You will find this article interesting.

From corrective maintenance to predictive maintenance

Industrial maintenance has undergone a great advancement throughout the last few years. New technologies enable industrial companies to stay ahead of problems and optimise productive processes and performance. Do you want to know the keys surrounding this transforming process? Are you aware of all the advantages of predictive maintenance? In this article of CLR’s blog you will find everything you need to know.