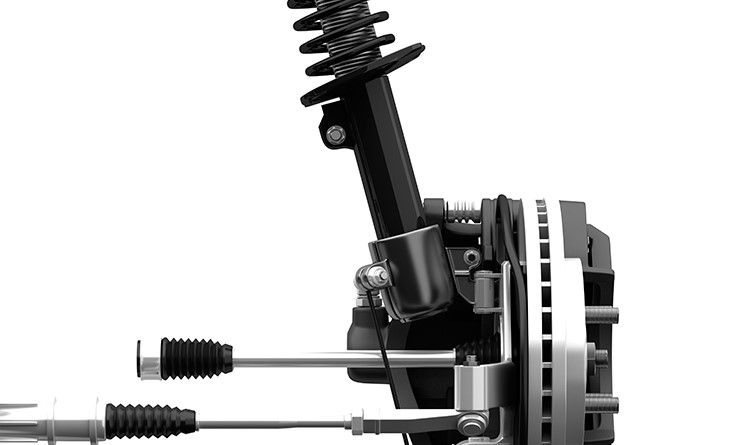

| Variable shock absorption system |

| The company that provides 25% of worldwide automobile shock absorber systems contacted us from Japan to find a solution which would enable drivers of the Audi RS6 to manually regulate the stiffness of the vehicle’s shock absorbers. |

| Thanks to its performance, our solution has been incorporated into all Audi RS models. |

| Problem: |

The biggest challenge of the project was to find a solution in which our gear motors would operate at maximum performance supporting high vibration levels. In addition to the difficulty of finding a system that would adapt to the location and the small volume of the vehicle design allowed was the added problem of finding a design that was able to withstand the harsh outdoor conditions such as rain or temperature spikes in excess of 50 degrees. |

| Solution: |

Our engineers were able to find a solution that not only met the demands of the automotive world, but with the high requirements of one of the leading companies in the sector. Our system exceeded the challenges of the project, withstanding high vibration levels, the harsh external conditions and adapting to the limited dimensions of the design.. Currently, Audi not only relies on our project for its RS6 model but has incorporated it into all of its RS range. |

|

Gear motors in cars

No matter where you need a travel mechanism, we help you to create it.

Learn more

|

|

Folding mirrors on cars and commercial vehicles

Gear motors located in rear-view mirrors require good resistance at reduced sizes. Our good results have made big brand names trust us.

|