It is increasingly common to argue in electromechanical engineering projects about what is more important: for a motor to deliver a high torque, or for it to yield a high maximum power. These concepts, for most professionals or purchase managers, are not completely clear. In this article we will try to answer what each of them is. Make a note!

You might be interested in: What is a servo motor and when is it used?

Firstly, in order to be able to tell them apart, we should first clearly specify their definition.

What is torque?

Torque is specifically the force offered by an engine. Each time there is an explosion in a cylinder, energy is released, which causes the engine to spin. Torque is used to measure this strength, which is delivered as rotation.

In a practical sense, we could say that torque is the driving force that the output shaft will have, which is completely independent of the time it takes to deliver this force – that would be the power.

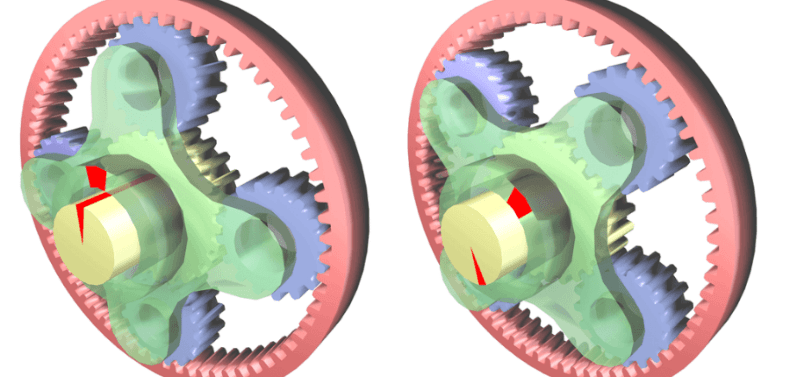

Overall, when applied to a gear motor, when we refer to torque (M) we are referring to the force exerted by the output shaft. It depends on each motor, and will increase based on the gear ratio (ratio of the gearbox).

Mechanical power and electrical power

Now that we can define the concept of torque, let’s more accurately dissect the concept of power. Power depends directly on the torque and rotational speed. If any of the two were to increase, power would as well. But, going more in-depth, can we define, calculate and differentiate between mechanical and electrical power?

– Mechanical power (W): This power can be compared to the torque (M). As we can see in the formulas below, in order to calculate this piece of data, it is necessary to know the torque and angular speed (w) (the latter is calculated using the output speed at the selected torque point).

W= M (Nm) x w (rad/s).

W =16,4 Nm (M at maximum yield in Nm) x speed (at maximum yield in rad/s).

10 r.p.m = 10× (1 revolution)/min×(1 min)/(60 s)×(2π rad)/(1 revolution)= (10 x 2 x π)/60= 1,047 rad/s

W =16,4 Nm x 1,047 rad/s= 17 W.

– Electrical power (W): this power depends on the electrical consumption and voltage. As we can see in the formulas, it is calculated using voltage (V) and electrical consumption (I).

W= V x I.

W = 24V x 1,4 = 33,6 w

The most common confusion in these cases is mixing up mechanical and electrical power. As we have seen, both pieces of data are completely unrelated in regards to the information they provide.

How can we use the parameter of torque to help us with the purchase of a small electric motor

Once the concepts of power and torque are defined, we can address this question. In this case, the decision depends on the buyer, since power and torque are two interrelated parameters. Torque and power are two specifications of the operation of an electric motor, since they tell us how much force it can generate, and how fast it can work. Analysis of the needs of the application will help you have an overall view of the technical specifications that our electric motor should comply with.

Do you still have questions? Do you need more information? CLR’s engineering and communication teams have developed a thorough guide for you. Download for free our guide “How to select the best electric motor in small drives” and start buying motors with full confidence.