When developing an application that requires an electric motor or gear motor to achieve an actuation, it is common for you to ask yourself: brushed motors or brushless motors? The choice will depend on the type of application that we are to develop, its size, and power requirements. The differences between these electric motors are given by their operation and structure. Learn about the specifics of each of them in this article.

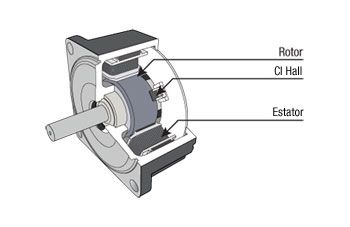

Brushed motors, as their name implies, use brushes connected to a hub in order to perform the polarity reversal in the rotor. These brushes are therefore in charge of mechanically commuting the current of the motor’s coils. On the other hand, brushless motors do not have a hub or brushes to reverse the rotor’s polarity; commutation in the coils is performed electronically through a motor controller.

What are the main differences between a brushed and a brushless motor?

The service life of a brushless motor is higher: since it has no brushes, there is no friction to generate wear or noise, and continuous maintenance is not required. On the other hand, the lifespan of brushed motors is lower: they have higher friction when reversing the polarity, they generate heat and sparks, and therefore the brushes get worn and have to be replaced, which demands a higher maintenance, with its associated costs.

At first, the brushed motor is cheaper than brushless motors. Additionally, unlike brushless motors, it does not require an electronic controller to operate, which uses expensive and complex circuitry.

Nonetheless, as a result of the loss of heat generated by the brushed motor, there is a higher energy waste, which has an effect on its efficiency. On the contrary, this is not the case for brushless motors, which are much more efficient.

The brushless motor offers a better relation between output power and size, and therefore has a higher performance. Contrarily, this relation is lower in brushed motors, which implies a lower performance.

Additionally, brushless motors also have a good relation between speed and torque, which is moderate for brushed motors, since when increasing speed, the brushes cause friction, and therefore, the torque is diminished.

Lastly, the brushed motor has mechanical limitations stemming from the use of brushes, which offers a smaller range of speeds when compared to brushless motors. For brushless motors, this range is higher.

This may interest you: Some tips for selecting small electric motors

What are the main applications of brushless motors?

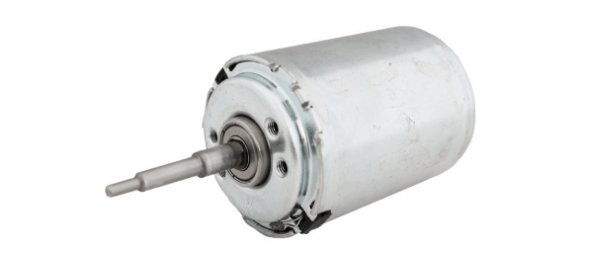

As we have seen, the brushless motor has a good power-to-size ratio. This makes it ideal for small applications where the space is limited, such as, for example, an electric skateboard. They are also interesting for applications requiring low power, such as a computer fan.

CLR, Compañía Levantina de Reductores, has a track record of over 40 years working with electric motors. Their team of highly-skilled engineers will assist you in the selection of the best actuation system for your application, or in finding the best custom solution. Do you want to learn more about which actuation system is best to set your project in motion? Download our gear motor guide!

hey great article. i feel iv learnt alot about brushed / brushless rc motors 🙂