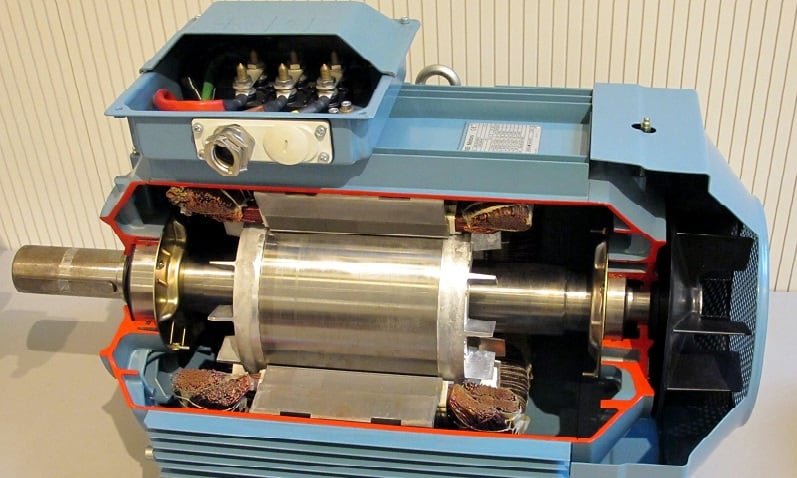

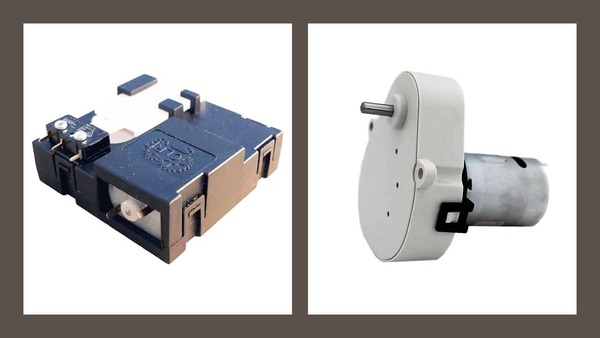

Electric motors let us obtain mechanical energy in the simplest and most efficient manner. Depending on the number of supply phases, we can find single-phase, two-phase and three-phase motors with coiled startup winding and with coiled startup winding with a capacitor. And choosing one or the other will depend on the necessary power.

If you are involved in a project and don’t know what type of motor you should use, this post will interest you! In it, we tell you about each motor and their differences. Let’s get to it!